YOUR NEXTAUTOMATIONSOLUTION

The demands on modern plants and machines are growing in all industries and competitive manufacturing needs greater efficiency and productivity of your industrial processes.

AutoNext can take you there as the right partner to lead the way.

We ensure an optimal solution to cover requirements for your application from plants to machineries and project to operation to help you substantially increase efficiency and flexibility while reduce your costs and time to market.

AUTONEXT can help you with ...

AUTONEXT makes difference with ...

Custom Solution

Whether you need simple or sophisticated, we have the rigth solution for your requirements

Expert Team

Our experts support you every step of the way from planning to implementation

Up to Date

The capabilities of AutoNext are constantly being expanded with new functions

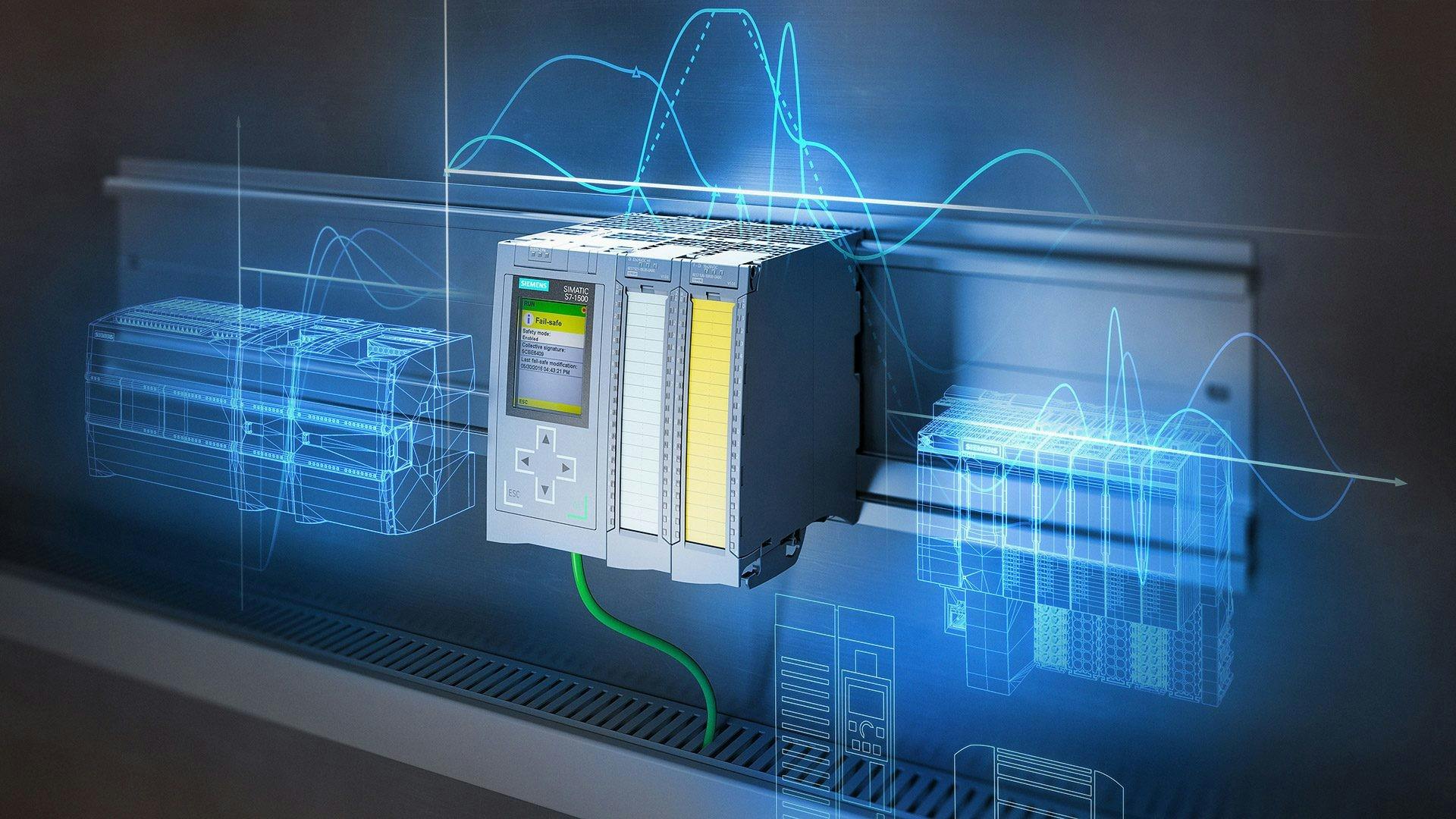

PLC Program

At the heart of all lean modern industrial automation systems are reliable, easy to maintain PLC controls, backed by a team of PLC programming developers that can quickly consult on, troubleshoot and resolve any issues that can jeopardize operations so it's critical to have a partner in automation that can provide experienced, creative and innovative PLC programming solutions that's up for any challenge that comes their way.

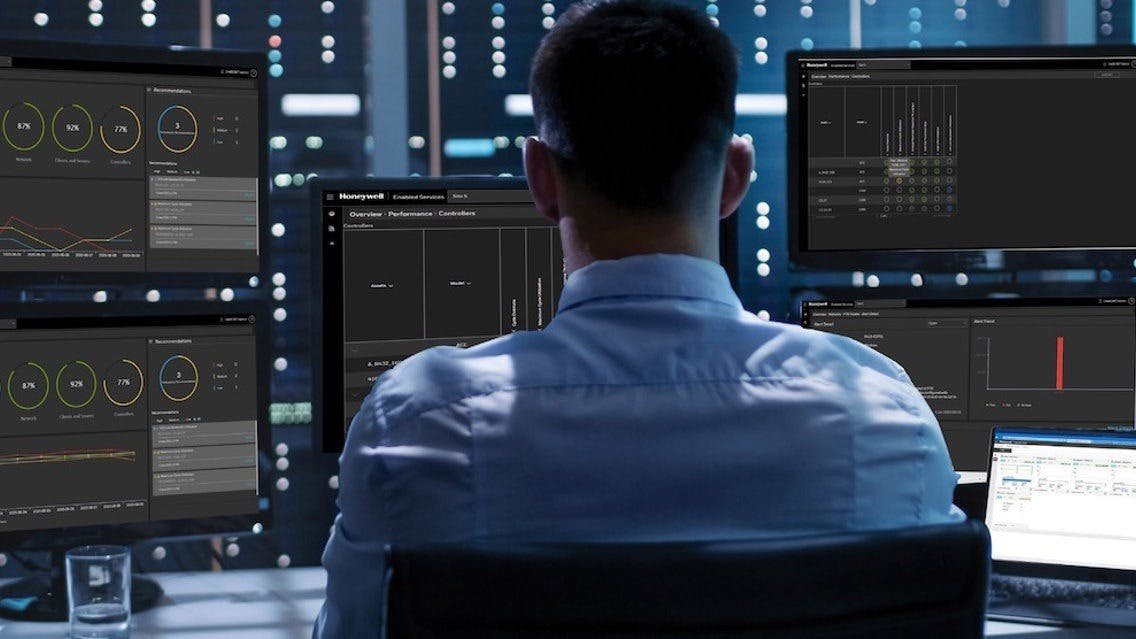

SCADA Software

Digitalization is noticeably changing our world and also the world of industry. The data volume in modern industrial plants is growing continuously. That brings new challenges for SCADA solutions: Enormous data volumes must be managed and archived for the long term. At the same time, production processes must be monitored and controlled as reliable, efficient, and productive as possible and they must be constantly optimized. Automation software is essential for ensuring a high level of functionality and efficiency in all phases of a plant's or machine's life cycle, from the field to the corporate management level.

HMI Panel

Equipment for monitoring and operator control is needed wherever people have to work with machinery and plants to performing tasks. The HMI provides your business with a real time textual or graphical view of system conditions and operations and also vital information. With HMIs offering monitoring, control, status reporting, data collection and other functions, you can maximize your PLC investment that ultimately driving both operational efficiency and profitability.

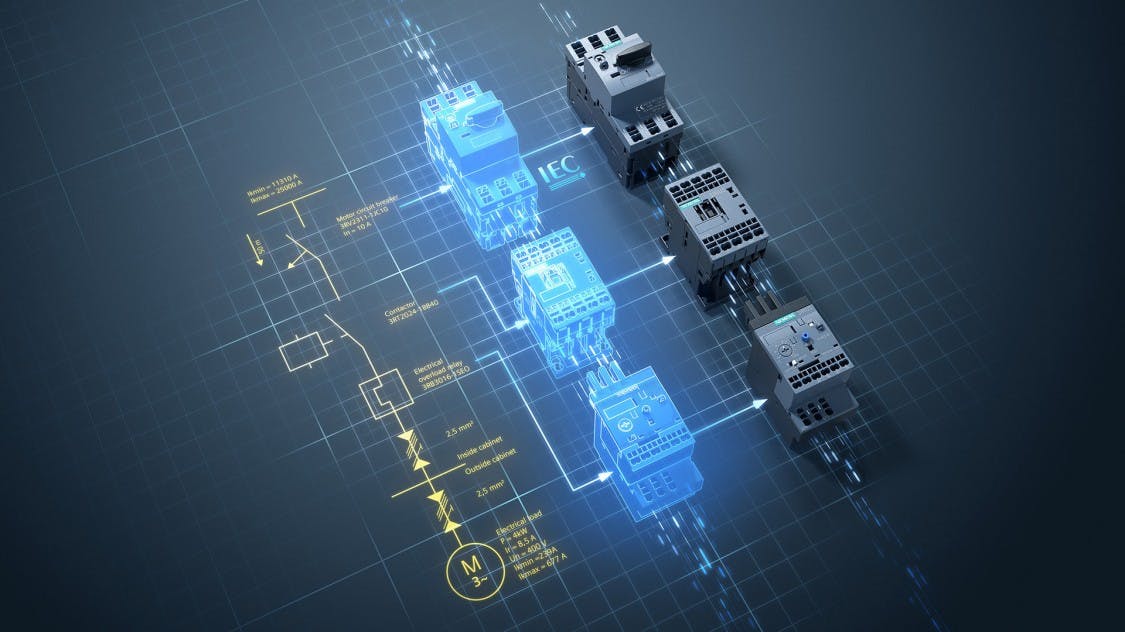

Electrical Design

Electrical planning is one of the essential steps in the development of a new machine or production plant. We Boosting engineering productivity with the next generation of Electrical Design for production systems. The complete design of production systems requires the design of their electrical systems. The central task in Electrical Design is the creation of 2D electrical control and power schematics. With Electrical Design software, you can complete these designs directly within the system in an integrated environment.

Control Panel

To ensure that electrical systems function and are available at all times, their individual components must be connected to each other reliably and without errors. The required control cabinets, terminal boxes, and control panels are manufactured according to the electrical planning. The planning documents contain exact dimensional drawings for the construction of the mounting plates and control panels. All of the hardware components we use are from leading manufacturers and have been carefully selected with regard to technical data and reliability.

Field Device

Our Instrumentation solution offers you innovative, single-source measurement solutions to increase plant efficiency and enhance product quality enabling greater process transparency and smarter decisions for your business. Because of an immense amount of conditions data is generated in a process plant. The benefits of accessing your field devices directly in your system is not disputed.

Industrial Network

Companies need industrial communication to control machines and plants, so Optimal utilization of the data generated in production also requires that Operational Technology (OT) and Information Technology (IT) networks seamlessly interact. With our complete range of solutions for industrial networking, we help you to lay an optimal foundation for digitalization and accompany you from the very start as you navigate digital transformation.

AUTONEXT steps to implement projects from A to Z are ...

Research

Identify customer needs and define requirements

Design

Design a system based on requirements that balance cost and need

Plan

Successful project starts with a clear plan and well-defined goals

Develop

Develop an implementable prototype that proves the concept

Install

Installation of all hardware and software from the control panel to the field device

Test

Test and troubleshoot comprehensively to satisfy project specifications

Integrate

The last step to ensure all systems are done and provide lifetime service and support

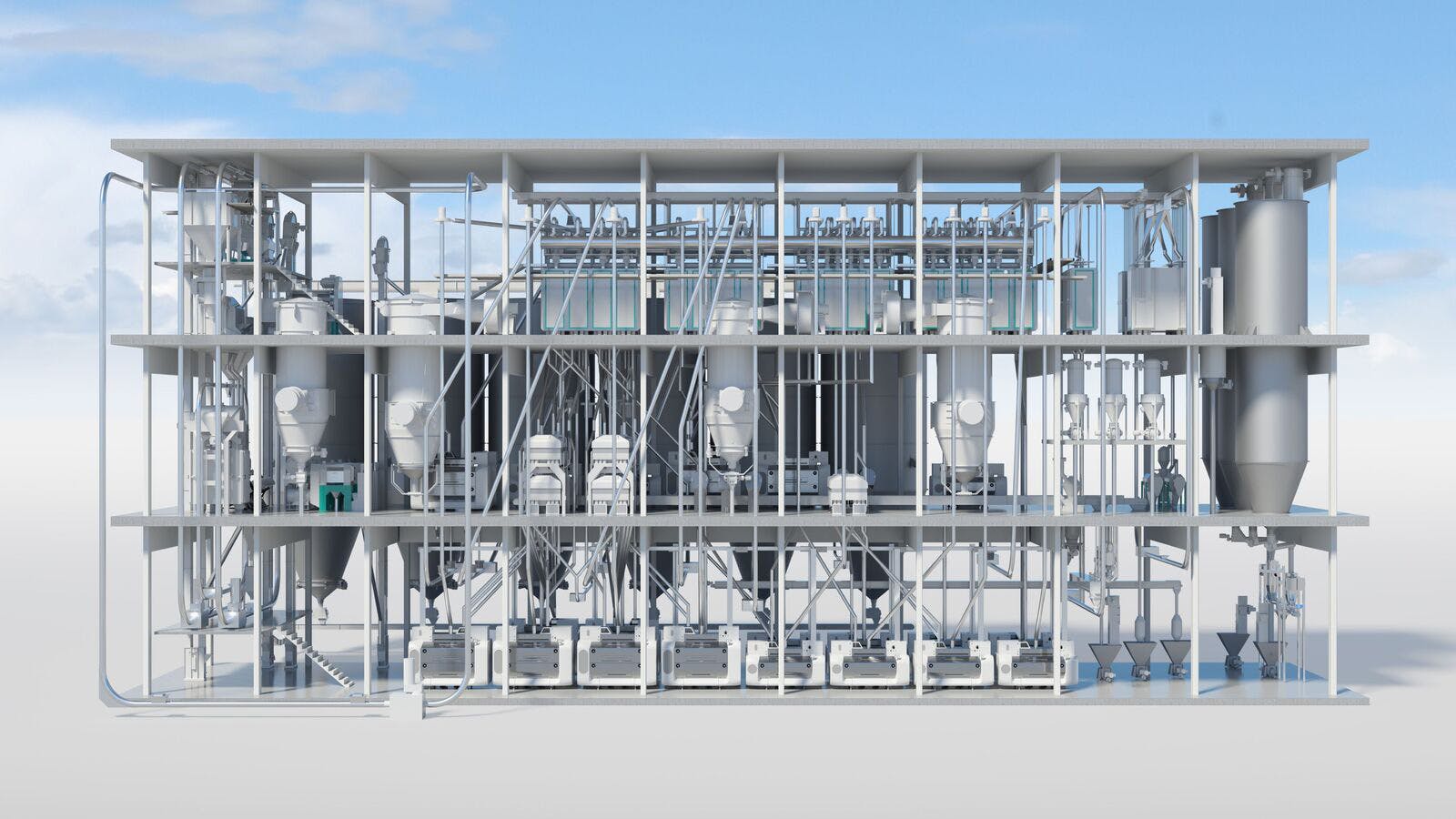

Animal Feed Processing Plant

we have extensive experience with automation control of animal feed production. We can ensure a reliable and optimized solution for your entire production process. We can provide the highest feed quality since we have full control of the process and provide built-in traceability. Additionally, our systems can be easily integrated into existing ERP and plant control systems via a database interface.

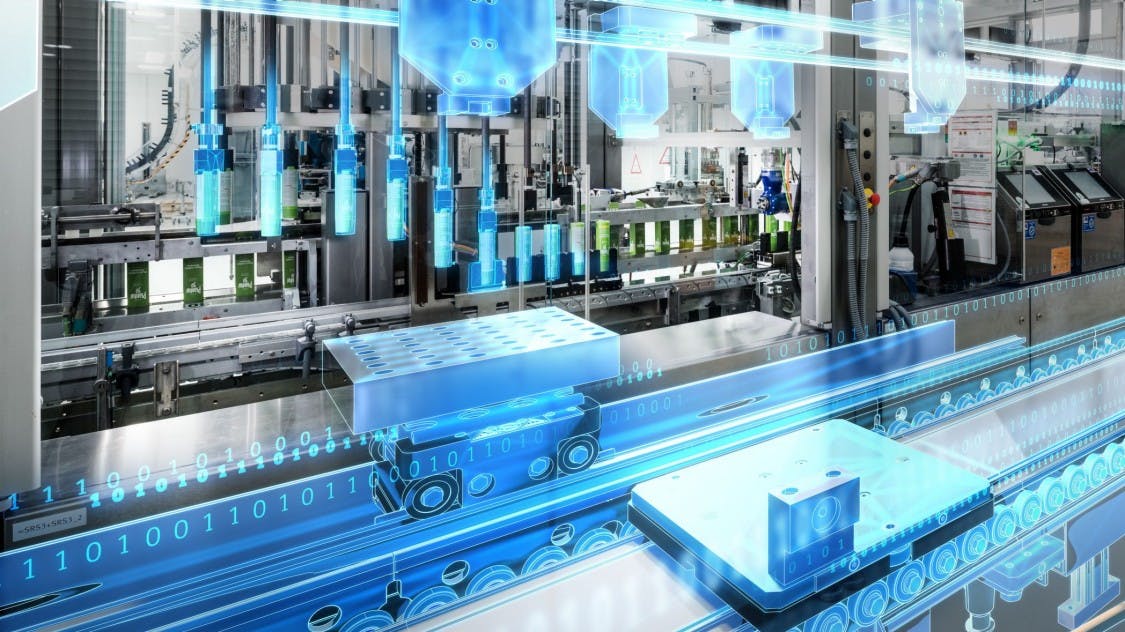

Packaging Machine Control

Materials manufactured are weighed on bagging scales and packed after being dispatched to product silos, then stitched bags are sent by being loaded to trucks through conveyors. Packaging lines have local screens in the process and operate with operators in charge of the related machine. Parameters of the machine vary depending on separate operation prescriptions according to the product type. Feed speed adjustments vary depending on the product type. Product reporting is made by comparing raw materials sent to the system and the number of bags coming out of the scale.

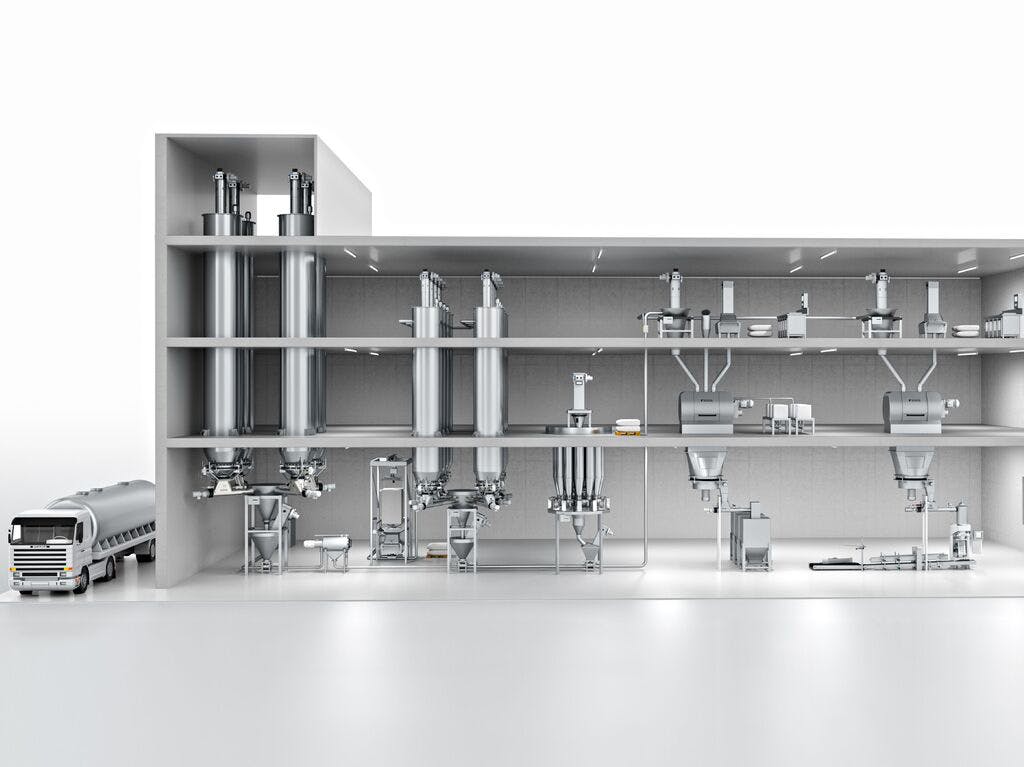

Premix Production Line

With the development of the feed industry, the requirements for feed and premix recipes and production technology are becoming higher and higher. Premix is a mix of vitamins and minerals. Some raw meat foods contain a premix to ensure that the nutrition is complete. With a premix, you prevent your pet from having nutritional deficiencies. The disadvantage of premix is that there are synthetic additives in the product. Dogs can get itchy and cats can develop bladder problems. Whether you are producing with premix, we surely can help you find the right automation solution for your premix process.

AUTONEXT partners to implement projects are ...

Consult

Develop and implement customized business strategies and roadmaps in close collaboration with our clients

Support

Efficient support over the entire life cycle of your plant or machine from the design stages through commissioning

Training

Learn how to use your automation system efficiently for higher availability and reduction of downtime in your production plant

Retrofit

Give your plant a second lease of life with a retrofit service to extend the lifetime of your machine with a factory revision

Our Vision

Each company has specific needs and requests that should be acknowledged. With our established and comprehensive knowledge of markets, we can offer our customers the best and most appropriate products, solutions, and services that can effectively and efficiently be used in their businesses.